Recently almost every medical device I design requires a stepper motor. After working with these motors so frequently, I’d like to share what I’ve learned about medical device stepper motors, the different types of stepper motor configurations, and how to drive stepper motors properly.

Stepper Motor Drive Configurations

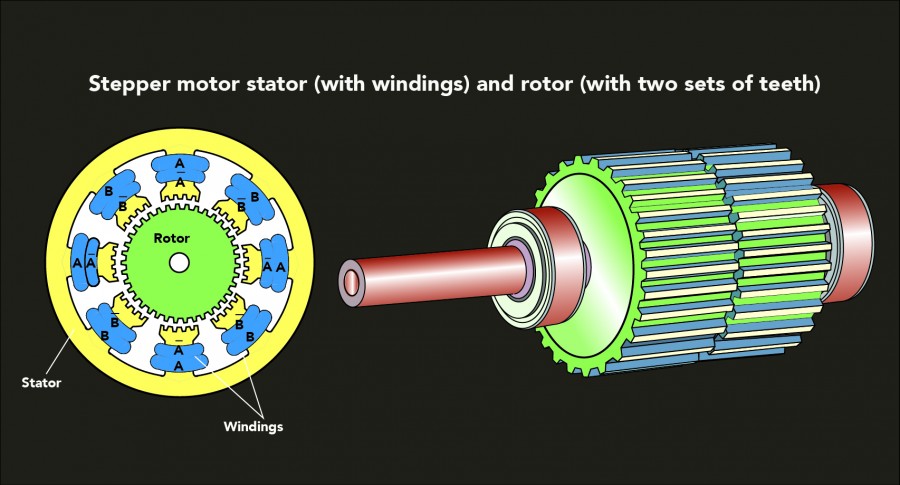

Stepper motors typically come in two motor winding configurations. Before selecting which configuration is appropriate for your application, you should understand the basic difference between the two. This choice will be important when selecting how to drive the motor.

Pro Tip: You can use a unipolar motor as a bipolar motor if you ignore the center tap. This can come in handy if a particular design of motor is only available in a unipolar configuration.

Stepper Motor Drive Signals

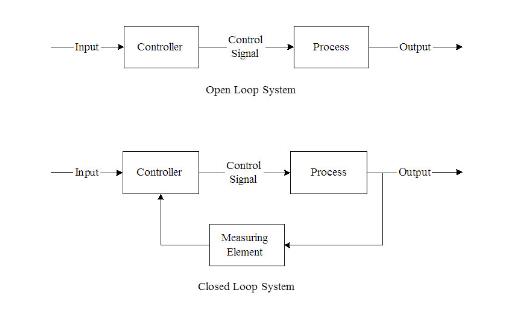

Typically three types of drive signals are used to control the motion of a stepper motor. Each drive type increases in complexity, but adds additional features and options.

A wave drive only energizes one phase at a time. Wave drives are simple to implement with basic hardware, but are rarely used. Because only one coil is energized at a time, torque is significantly reduced.

Stepper Motor Drive Circuits

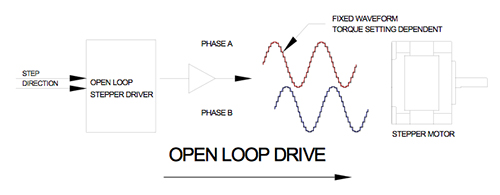

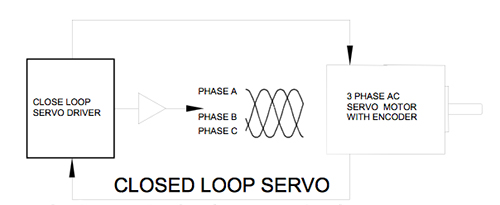

The most common methods for driving a stepper motor include a simple constant voltage or L/R (L refers to electrical inductance and R stands for electrical resistance) driver, a chopper drive, or a sine wave/micro-stepper driver.

Stepper Motor Integrated Drivers

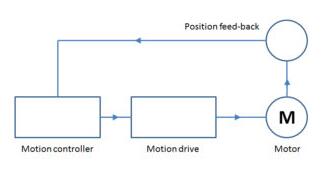

Once a stepper motor hybrid has been selected to suit its mechanical requirements, the next thing is to get that motor turning. It is easier than ever to make a motor operational by selecting an off the shelf stepper motor driver IC or development board. Many of these boards provide features such as current feedback, built in acceleration profiles, and even onboard path planning for more complicated motion control.